Evaluating the Environmental Durability of Winch Relay Factory Components for Long-Term Use

In demanding outdoor applications, the durability of equipment becomes as important as its performance. A relay used in winching systems is particularly exposed to changing environments that involve dust, humidity, and fluctuating temperatures. To determine whether solutions from a Winch Relay Factory meet these requirements, one must explore how these products are engineered and whether their protective designs align with the needs of real-world use.

Environmental Resistance in Outdoor Operations

Relays used in winch systems often face prolonged exposure to harsh elements. Dust infiltration can interrupt electrical contact, while moisture may lead to corrosion or even short circuits. Outdoor durability depends largely on housing design, sealing quality, and the materials chosen for internal components. Factories that specialize in relays intended for winching typically test their products against these conditions, ensuring that protective casings resist both mechanical and environmental stress.

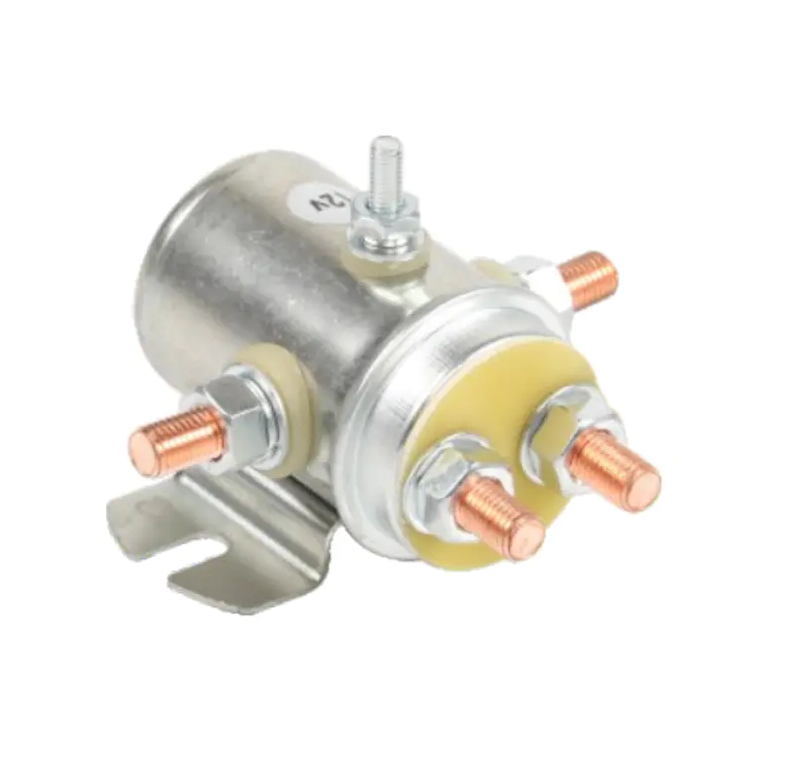

Material and Structural Considerations

The resilience of a relay is not solely about external sealing but also about the robustness of the internal design. Contacts must be made from alloys resistant to oxidation, while insulation materials should withstand the heat generated during continuous load operations. The body of the relay, whether metal or polymer-based, must also offer stability under vibration and shocks. By paying attention to these structural details, manufacturers improve not just the life span of their products but also the safety of users who rely on consistent performance.

Importance of Testing and Certification

Durability claims are only as strong as the tests that validate them. Environmental simulations such as thermal cycling, salt spray exposure, and dust chamber testing are commonly used to assess performance. Products that pass internationally recognized standards for water and dust resistance, such as IP ratings, provide users with confidence that the relay will not fail in outdoor scenarios. This testing process ensures that relays can endure long-term usage without compromising operational efficiency.

Application in Harsh Conditions

When mounted on vehicles or outdoor machinery, winch relays must be capable of operating without frequent maintenance or unexpected breakdowns. Their ability to resist harsh conditions directly translates into reliability during critical tasks such as vehicle recovery, industrial lifting, or marine operations. A well-engineered relay reduces downtime, enhances safety, and extends the overall service life of the winching system, making it an essential investment for both casual and professional users.

The question of whether winch relays can withstand challenging environments ultimately depends on the quality of design and the rigor of testing carried out during production. Products developed with careful attention to sealing, material resilience, and environmental validation are more likely to perform reliably in real-world conditions. For users, choosing equipment with proven resistance features ensures that operational safety and efficiency are maintained even in the harshest outdoor settings.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness