CNC Milling Machines: The Future of Precision Manufacturing

CNC milling machines are among the most widely used machines for cutting metal. These machines use rotary cutters to remove material from a workpiece by advancing a cutter into the metal. The cutting tool can move in multiple directions—up, down, and across the workpiece—allowing for complex shapes and detailed features. CNC milling is ideal for producing parts like gears, brackets, and housings, offering high precision and a smooth finish.

CNC lathe machines are used for turning operations, where the workpiece is rotated against a fixed cutting tool. This type of machine is perfect for creating cylindrical or round metal parts such as shafts, bolts, and bushings. The cutting tool moves along different axes to create precise diameters, threading, and tapering. CNC lathes offer excellent accuracy and can handle both simple and complex tasks.

Laser cutting machines use a focused beam of high-energy light to melt or vaporize metal. This technique provides extremely clean and precise cuts, making it suitable for intricate designs and thin metal sheets. CNC laser cutting is widely used in industries that require fine details and high-speed cutting, such as aerospace, automotive, and sheet metal fabrication.

CNC plasma cutting machines use an ionized gas (plasma) to cut through metal. Plasma cutting is especially effective for cutting thicker sheets of metal at higher speeds compared to traditional methods. This technique is often used in industries like construction and heavy equipment manufacturing, where thicker materials are commonly required.

Water jet cutting uses a high-pressure stream of water, sometimes mixed with abrasive particles, to cut through metal. This method is advantageous for materials that cannot withstand high heat, as it generates little to no heat in the cutting process. CNC water jet cutting is suitable for a wide variety of materials and offers high precision with a clean finish.

https://www.zjgycnc.com/product/milling-turning-multifunctional-cnc-machine/

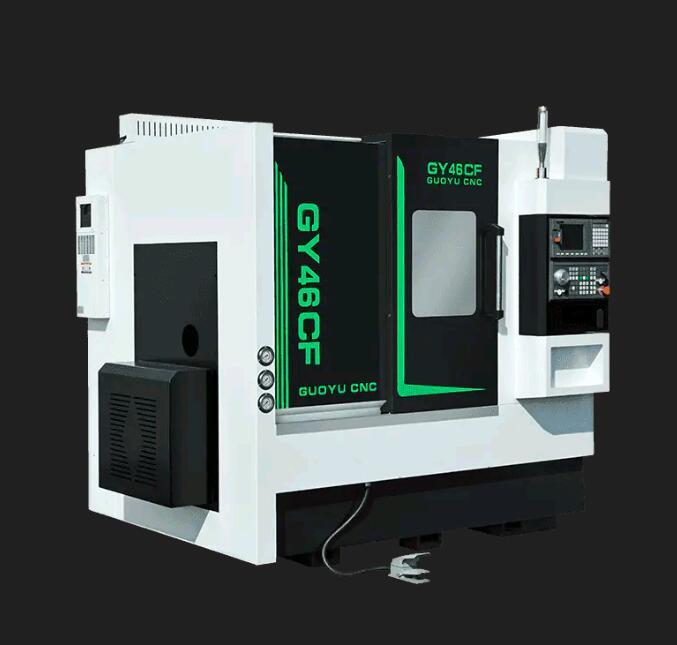

45° slant bed base structure, with strict aging treatment, smooth chip removal, and reasonable cutting space.

Independent sleeve type spindle unit imported angular contact spindle bearing, and through precise dynamic balance, the spindle rotates stably at high speed.

Wide precision linear guideway and center precision ball screws are adopted to enhance the overall rigidity and accuracy retention of the machine tool.

Widened T-type middle slide plate, which is convenient for installing gang-type tools, horizontal turrets, and live tool units.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness