The Art of Automotive Mould: Crafting the Future of Car Design

Automotive molds play a crucial role in the manufacturing of vehicle components, allowing for the precise shaping of materials used in car production. These molds are used in a variety of processes, from creating exterior panels to interior parts, and they ensure that each component meets the required standards for quality and performance. Here, we’ll take a look at some of the most common types of automotive molds.

1. Injection Molds

Injection molding is one of the most widely used techniques in the automotive industry. In this process, plastic material is melted and injected into a mold cavity under high pressure. This method is ideal for producing high-precision, complex parts like dashboard components, trim pieces, and connectors. Injection molds are favored for their ability to produce large quantities of parts quickly, making them cost-effective for mass production.

2. Compression Molds

Compression molding involves placing a pre-measured amount of material, often rubber or thermoset plastic, into a heated mold. The mold is then closed, and pressure is applied to shape the material. This method is commonly used for making automotive parts such as seals, gaskets, and weatherstripping. Compression molds are valued for their simplicity and the durability of the parts they create, especially for rubber-based components.

3. Blow Molds

Blow molding is used for creating hollow plastic parts such as fuel tanks, air ducts, and other large automotive components. In this process, plastic is heated and blown into a mold to form the desired shape. This method allows for the efficient production of lightweight, hollow parts, making it particularly useful in automotive applications where reducing weight is a priority.

4. Die-Cast Molds

Die casting is typically used for metal parts in the automotive industry. In this process, molten metal is injected into a mold under high pressure. Die-cast molds are often used for producing small, complex, and durable components such as engine parts, transmission cases, and housings. The precision of die casting ensures that these critical components meet stringent quality standards.

https://www.bumpermould.net/product/bumper-mould/plastic-injection-front-rear-bumper-mould-for-2021-benz-gls.html

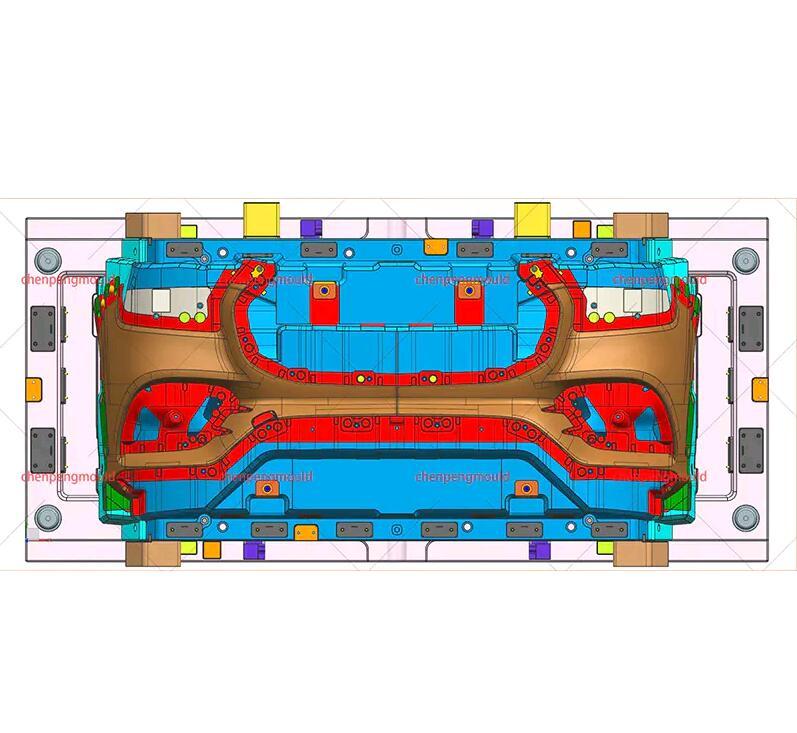

Mould Name Benz GLS Bumper Mould

Material PP EPDM

Bumper Size 2100*610*560mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2550 x 1200 x 1050mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness