-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Evènements

-

Blogs

-

Offres

-

Emplois

-

Courses

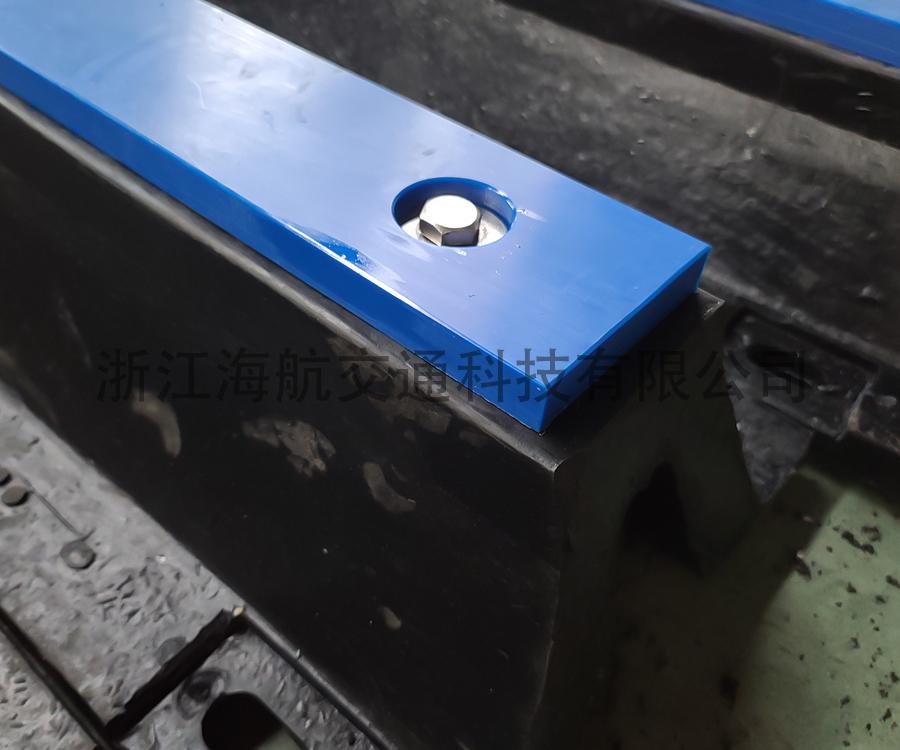

What Features Make a V Type Rubber Fender Reliable for Docking?

In maritime operations, vessel protection during docking and mooring is crucial to prevent damage to both ships and port infrastructure. One of the widely used solutions for this purpose is the V Type Rubber Fender. This specialized fender is designed to absorb impact energy, reduce friction, and provide a reliable barrier between vessels and docking structures.

The V Type Rubber Fender has a distinctive V-shaped design that allows it to handle various angles of contact efficiently. When a ship approaches a berth, the fender's structure compresses and distributes the impact force over a larger area. This reduces localized stress on the hull, minimizing the risk of scratches, dents, or structural damage. Its shape also helps accommodate vessels of different sizes, making it a versatile choice for ports handling a variety of ships.

Manufactured from high-quality rubber compounds, the V Type Rubber Fender offers durability and resilience under harsh marine conditions. Rubber's inherent elasticity allows the fender to return to its original shape after repeated impacts, providing long-term performance with minimal maintenance. The material is resistant to saltwater corrosion, UV exposure, and temperature fluctuations, which are common challenges in harbor environments.

Installation of a V Type Rubber Fender is typically straightforward. The fender can be mounted on quay walls, piers, or floating docks using brackets, chains, or bolts. Its V-shaped profile ensures consistent contact with the vessel, even in situations where water levels or ship drafts vary. This adaptability reduces the need for frequent adjustments and ensures continuous protection for moored vessels.

One of the advantages of using a V Type Rubber Fender is its ability to absorb energy efficiently. The V-shaped design, combined with the elasticity of the rubber, converts kinetic energy from docking maneuvers into deformation energy. This process lowers the impact forces transmitted to both the vessel and the structure, preventing damage and improving operational safety. Ports that rely on heavy cargo vessels or ferries often benefit from this energy absorption capability.

Maintenance of a V Type Rubber Fender is relatively simple due to the material's resistance to wear and environmental conditions. Regular inspections for abrasion or deformation are usually sufficient to ensure continued performance. If needed, individual fenders can be replaced without major disruptions to port operations, making them practical for long-term use.

The V Type Rubber Fender also enhances safety during docking operations. By providing a consistent buffer between the ship and the quay, it helps reduce sudden jolts or uncontrolled contact that could endanger crew members. The fender's design ensures stable and predictable interaction with the vessel, which contributes to safer mooring procedures.

In addition to commercial ports, the V Type Rubber Fender is widely used in shipyards, marinas, and ferry terminals. Its combination of impact absorption, durability, and ease of installation makes it suitable for a variety of marine environments. Many ports choose this fender type to standardize vessel protection across different docking points.

The V Type Rubber Fender is an essential component for safeguarding vessels and port structures. Its V-shaped design, resilient rubber material, and energy absorption capability make it a reliable and adaptable solution in maritime settings. By reducing impact forces, preventing damage, and improving safety, it plays a significant role in efficient and secure docking operations.

https://www.zhhatrte.com/product/rubber-fender/v-type-rubber-fender/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness