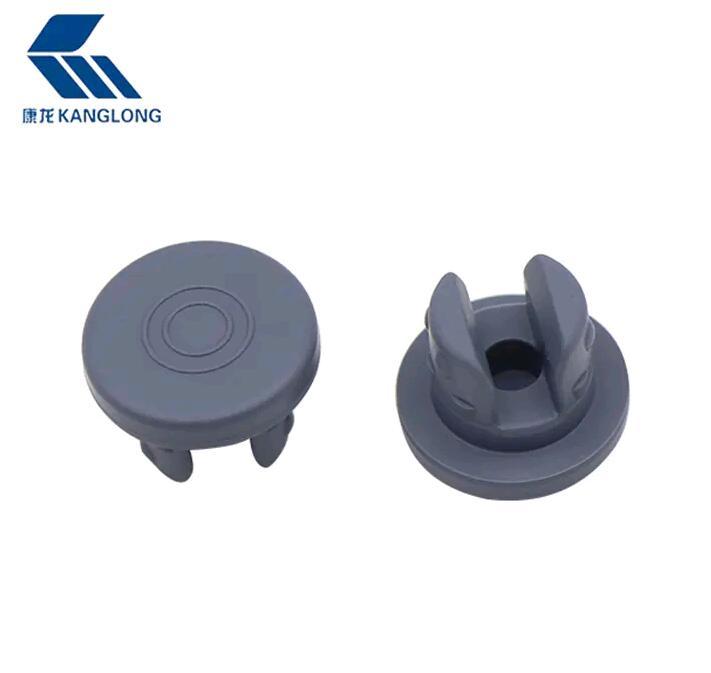

High-Quality Butyl Rubber Stoppers for Medical Equipment

Medical lyophilization stoppers are designed to provide an airtight seal that protects vials from air, moisture, and microbial contamination. The stoppers have a specific design, often including a smooth sealing surface and precise dimensions to ensure a tight fit with the vial neck.

Their sealing capability is especially crucial during and after the lyophilization process, as maintaining vacuum or inert gas inside the vial prevents degradation of sensitive products.

Butyl rubber naturally has low permeability to gases such as oxygen and moisture vapor, which are common causes of pharmaceutical degradation. This feature helps protect lyophilized drugs by maintaining a controlled environment inside the vial, significantly reducing the risk of oxidation or moisture absorption.

Freeze-drying involves freezing the product, reducing pressure, and then removing water by sublimation. This process requires stoppers that can withstand low temperatures and sudden changes in pressure without compromising the seal or physical integrity.

Butyl rubber stoppers used for lyophilization are engineered to be flexible and resilient, allowing them to contract during freezing and expand as pressure changes, maintaining vial closure without cracking or deformation.

Medical-grade butyl rubber stoppers comply with strict pharmaceutical and medical regulations, ensuring they are biocompatible and free from harmful substances such as heavy metals, plasticizers, or additives that could leach into the medication.

Manufacturing processes also focus on cleanliness, often including sterilization by gamma radiation or ethylene oxide, to ensure the stoppers do not introduce contamination.

https://www.klstopper.com/product/pharmaceutical-rubber-stopper/lyophilization-freezedried-butyl-rubber-stoppers.html

Excellent sealing performance

Replacement of barrier rubber stoppers

Provides special chlorobutyl rubber formula for good compatibility

With pharmaceuticals Special treatment process and the most stringent process control ensure the cleanliness of the rubber stopper

Microbiological testing is to ensure the safety of rubber stoppers

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness